Steelmaster SM-PB300-4000CNC2 Hydraulic Pressbrake

Steelmaster SM-PB300-4000CNC2 Hydraulic Pressbrake : Ask for Price

DONT BE LEFT IN THE DARK - ASSET HAVE THE BEST FULL TIME TECHS TO SUPPORT AND SERVICE YOUR MACHINERY.

AUSTRALIAS BEST SERVICED, SUPPORTED & USER FRIENDLY GRAPHIC CONTROLLER

GET IN FOR YOUR DEMO AT OUR HUGE MACHINERYHOUSE - ASSET

Description

Our new ibend CNC2 Series offers you everything you want at the right price.

Feature packed and driven by the powerful ibend Touch Screen CNC controller, we have also included full front and rear safety light guards.

No more plus, plus or hidden costs, this is it! Deep side throats, ball screw back gauges, quick release tool clamping (Up To 170Ton), sliding front supports – this list goes on and on!

Operators can’t do without it!

Features

?hydraulic synchronised positive stop design, electronically controlled by CNC ibend Programmable controller assuring accurate repeatability and ease of use..

?CNC ibend programmable precision ball screw back gauge with adjustable height finger stops.

?segmented heavy duty 86° offset top tool, segmented for return bend clearance, complete with European style quick release tool holders.

?full length Multi Vee bottom block with a smart selection of openings also including safety edge vee ('V') for over bending.

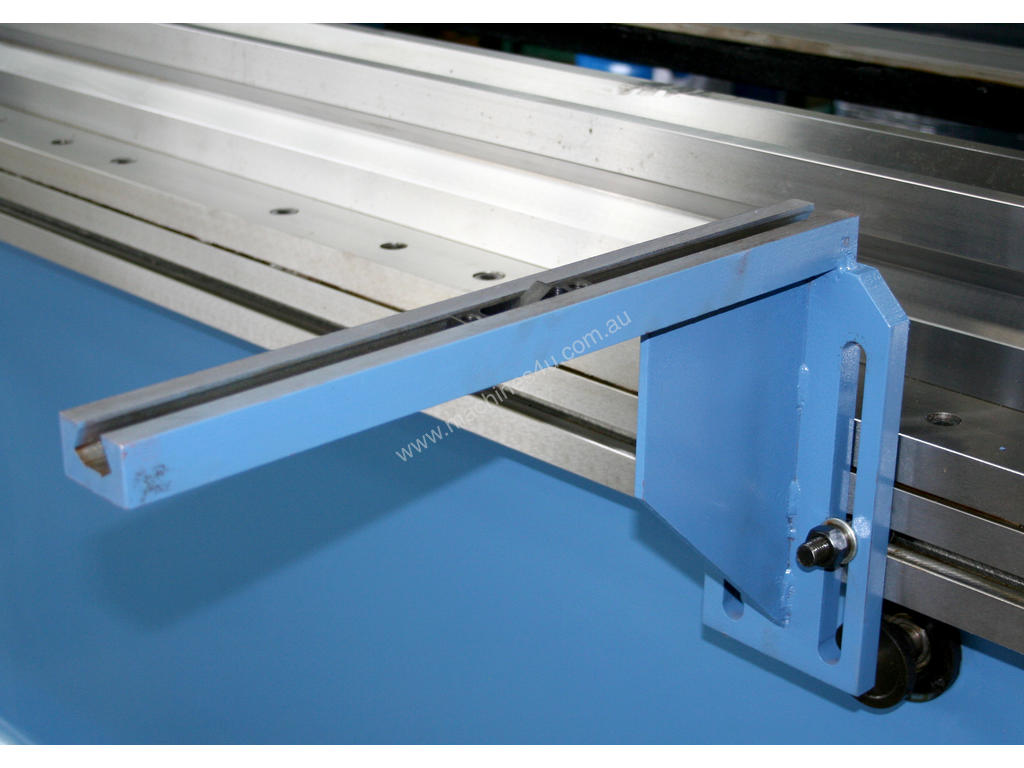

?ball screw drive back gauge with quality support fingers also with vertical adjustment.

?sliding steel fabricated sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required height.

?conveniently mounted control box on pendant for quick swivel and adjustments.

?integrated hydraulic system allowing rapid approach switching automatically to slow bend.

?modern designed pendant foot pedal operation with stainless braided cable.

?variable hydraulic pressure control valving fitted standard.

?safety and material selection bending charts mounted on front beam for easy access.

?prices includes front and rear safety Laser Light Guarding to Australian compliance.

?in addition, we can also offer 3 ~ 7 axis proessbrakes to suit your requirements.

?CE compliant.

ibend Features

?the most user friendly touch screen CNC controller on offer.

?backed by the support team at Asset Plant offering direct contact.

?large user friendly Touch Screen.

?easy Job Selection.

?select existing jobs from the library.

?jobs can be named and saved for future use. A virtually unlimited number of jobs can be saved.

?jobs open with all relevant data like bend sequence, material thickness, right Tool, Die & V, angle corrections, which bends were done from front or rear etc. This saves lots of set-up time.

?each operator can have his own password with his own job library.

ibend – Easy steps to put you in production in no time!

Step 1. FASTDRAW: Simple & Easy!.....

Simply touch the grid to draw the subject profile.

Press OK to return to the main screen.

Step 2. Simply touch on the dimension or angle of the profile on the right to edit the value on the popup keypad.

Step 3. So simple!........ See the profile on one side for easy editing….. and the folding simulation on the other!

• View the actual folding sequence simulation on the graphic of a Press Brake as you fold in real time or screen sequence mode.

• Change folds from front to rear to maximise production.

• Step through the whole sequence without wasting time or material.

• Touch the “Auto fold” button or set the fold sequence manually simply by entering the sequence (1 2 8 7 6 5 3 4 for the example).

Step 4. Enter material thickness and width.

Step 5. Select the right tool and die from the library and start production.

Technical Data Snap-Shot

?300 Ton Bending Capacity

?4000mm Bending Length

?3600mm Distance Between Frames

?420mm Side Throat Depth

?250mm Ram Stroke

?500mm Open Height

?Italian DSP laser guards included

?25.0Kw / V Motor Power

?4650mm x 2350mm x 2990mm Footprint

?25200Kg Weight

#### Please note - machine pictured is similar machine - not exact offered####

#######################################

Most Machines Can Be Demonstrated Under Power at 118 Logis Blvd Dandenong South, Vic.

Or See Videos or online

Otherwise call Us On And We Can Discuss Your Requirement

Asset Offer Full Sales Service, Parts & Accessories For Your Support!!!

#######################################

********************************************

Need more details? Can't find what you are looking for?

********************************************

We have many more items available than listed here.

Our main Product we offer is Steelmaster with a detailed listing below.

Steelmaster Metalworking Hydraulic Pressbrakes.

When looking for a quality Metalworking Hydraulic Pressbrake, look no further than Steelmaster Industrial. Steelmaster Industrial's Metalworking Hydraulic Pressbrakes offer the Sheetmetal worker a very high quality machine with superb features and tight tolerances at reasonable prices. Steelmaster carries over 20 models of Metalworking Hydraulic NC & CNC Pressbrakes in stock at all times for quick shipments. Steelmaster Industrial's ever growing line of Metalworking Hydraulic Pressbrakes consists of NC Operated & CNC along with a large range of tooling & accessories. Depending on your needs we have the model for you, starting with our cost effective NC machine to our ibend CNC2 Graphical Models. You won't be disappointed.

NC Operated Hydraulic Pressbrakes

With many models to choose from our Hydraulic NC Pressbrakes offer the best ``bang for the buck``. The NC model comes standard with an Etsun E200 fully programmable controller operating the Y & X Axis. Large side throats and also distances between the frames are also an added bonus. Full Top & Bottom tooling is supplied, front sheet supports, & ballscrew backgauge system. We fully believe that we have packed our Hydraulic NC Pressbrakes with as many features that we can think of to assist you with working smarter -- not harder! We offer our Hydraulic NC Pressbrakes in sizes from 1320mm x 30Ton ~ 6000mm x 600Ton with larger models available on request. Safety Laser Light Guards are an addition, however we offer these at a very competitive price --

CNC Operated Hydraulic Pressbrakes

Steelmaster Industrial offers our new ibend CNC Controller on our CNC range. This would have to be the best CNC system on the market for power and ease of operation. Our Hydraulic CNC Pressbrakes have been fitted up to offer you the best selection of features. In addition to the NC models our CNC models offer, sliding front sheet supports, ibend CNC graphical controller, quick clamp tool holders, quality imported precision backgauge system and fingers & safety light laser guards are included!!!

MAKE YOUR NEXT PURCHASE AN ``ASSET`` TO YOUR COMPANY!

Please contact us for more information.

Asset Plant & Machinery - Steelmaster Machinery

118 Logis Boulevard Dandenong South VIC 3175

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print