6500mm x 1.2mm CNC Slitter Folder, 1000mm Throat, CNC Controller

6500mm x 1.2mm CNC Slitter Folder, 1000mm Throat, CNC Controller : $138,850 AUD ($152,735 Inc. GST)

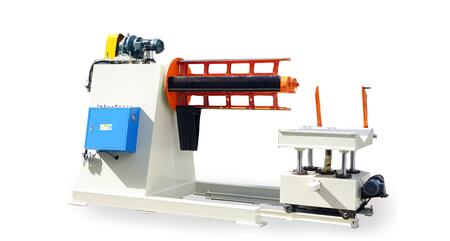

MM6512CNC. Slitter Folder: Machine Makers 6500mm x 1.2mm Slitter Folder, 1000mm Throat,

6 - 9 Frames, CNC Graphical Controller and Associated Equipment. Volt

Machine

Type Long bed 6512 ACS apron folder

Working length 6500mm

Number of Heads 7

Fold Cylinders 7

Clamp Cylinders 7

Bending range 0 to 135 degrees

Throat depth to Slitter 1000mm

Jaw face width 34mm

Hinge 7 points Parallelogram linkage

Jaw/apron operatio Hydraulic double acting cylinder

Cycle time approx. 8 seconds for maximum fold variable

Gauging method Variable 0.40mm to 1.60mm by adjustment

Folding Capacity

Material yield Strength G550

Thickness 1.2mm

Slitter Unit

Type Overarm Mounted

Knife Diameter 80mm

Material D2 Hardened and Ground to 60 – 62Rc

Drive System Electric motor and wire rope

Guiding System Large section linear guide

Cutting speed 720mm per second

Cycle time approx 23 seconds for full 6.5 meter slit

Control Feature

Automatic Functions Angle Range of 0 to 135 degrees

Safety Features: E-stop circuit,

Full Length Kick rail

Electric interlock

Two stage clamping

Emergency stop

We can offer 6500mm ~ 8200mm Lengths - 1.2mm & 1.6mm

Throats upto 1200mm Deep, NC and Full CNC - Call us with your requirements

Automatic Control System (ACS)

The Automatic Control System is a fully integrated control that allows the operator to pre-program and store up to 1000 profiles.

The operation of the control is simple and reliable. All the backguage positions and fold angles are easily programmed and stored.

After the machine finishes each bend, the backgauge moves to the next required position in the sequence. The backgauge can

be set for slitting operations also. The HMI is a flat screen, touch panel to display all information in a graphical format which is very

user friendly. The graphical interface allows the operator to up load programs from drawings of commonly used profiles. This control

also has network capability.

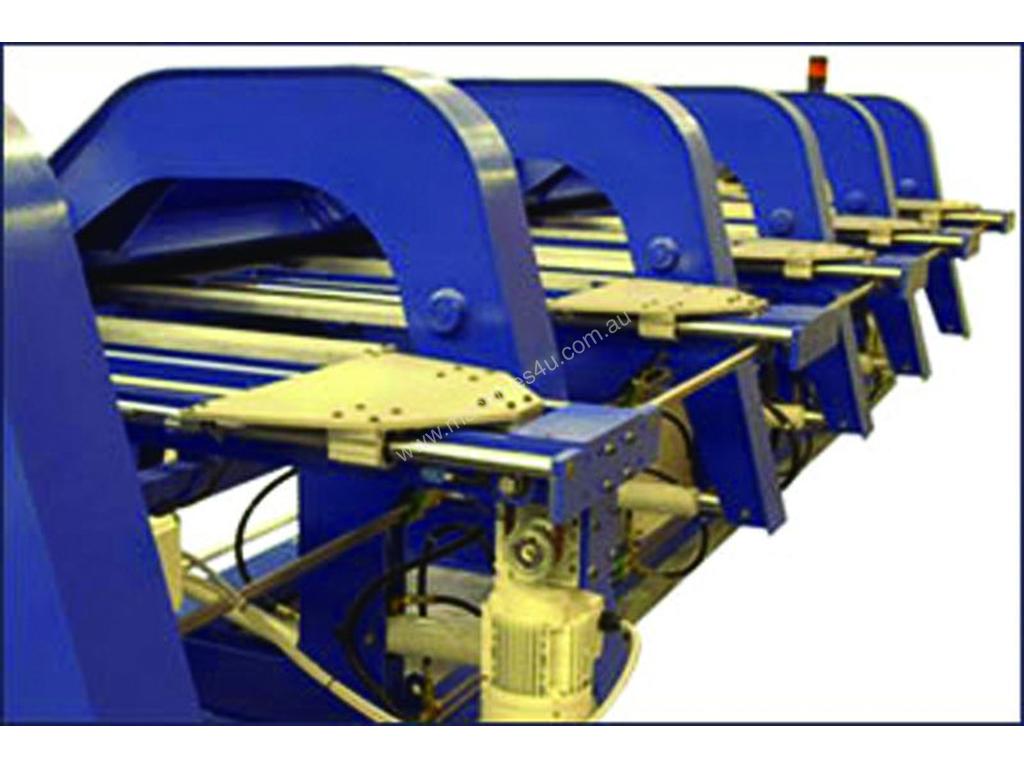

Backgauge Systems

The Backgauge systems utilize fully integrated control components providing accurate material positioning, and eliminate the

requirement to mark the fold and slit positions on the material.

The Backgauge control systems use purpose built linear guide rail assemblies, featuring steel reinforced timing belts and aluminium pulleys,

transferring drive from a geared motor with flux-vector drive, giving highly accurate positioning. The Backgauge assembly features multiple

fingers per station to ensure the material is straight when pushed into the machine. The Backgauge operates across the full width of the

machine and is able to measure material sizes down to 10mm. Most profiles can be produced using the material positioning system

without any manual measurement of material.

Hydraulic Speed Control

Clamp and apron speed control allows the operator to fine tune the speed of the folder. Using parameters on the ACS software, the operator

can adjust the Clamp approach speed, Clamp speed, Clamp raise speed, and the speed up and down of the folding apron. The idle speed of

the pump is also adjustable to give quiet and efficient operation.

Inclusions:

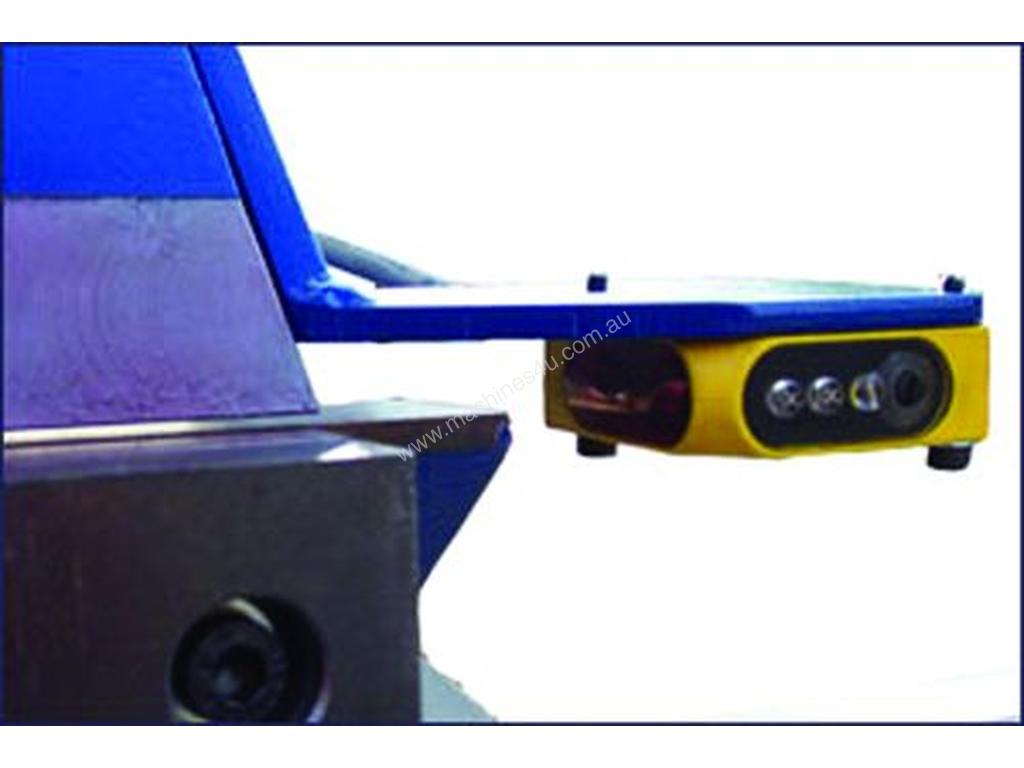

Safety Light Laser Guards On Top

Hardened Strip On Top Beam

MAKE YOUR NEXT PURCHASE AN ``ASSET`` TO YOUR COMPANY!

Please contact us for more information.

Asset Plant & Machinery - Steelmaster Machinery

118 Logis Boulevard Dandenong South VIC 3175

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print